As a technician with a decade of experience in the industry, I have witnessed firsthand the evolution and critical importance of die-cast aluminum parts in various manufacturing sectors. This article aims to provide a comprehensive overview of die-cast aluminum parts, their technical challenges, the primary dimensions for detection, and the crucial role of coordinate measuring machines (CMMs) in ensuring their quality and precision.

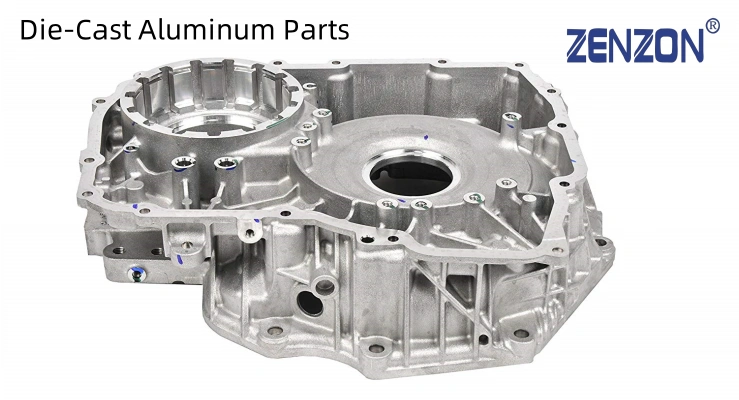

1. Basic Introduction of Die-Cast Aluminum Parts

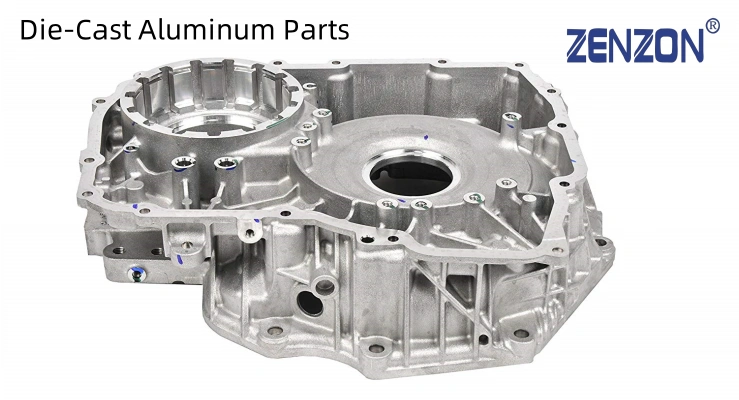

Die-casting is a versatile manufacturing process used to produce accurately dimensioned, sharply defined, smooth, or textured-surface metal parts. Aluminum, due to its excellent mechanical properties, light weight, and resistance to corrosion, is a popular choice for die-casting. Die-cast aluminum parts are widely used in automotive, aerospace, electronics, and consumer goods industries, contributing significantly to their performance and durability.

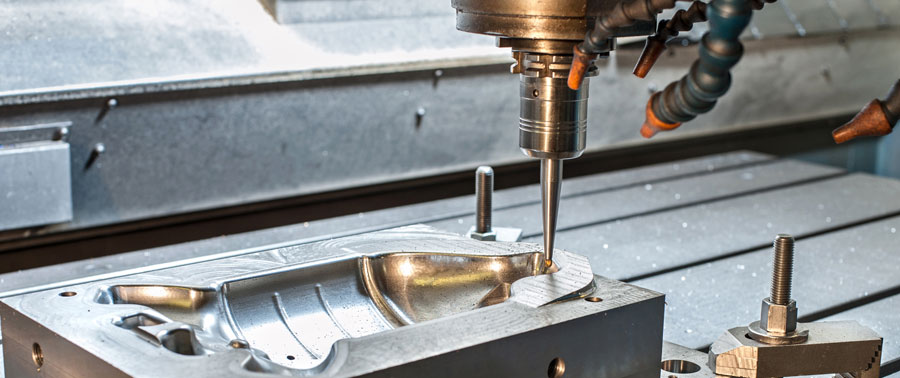

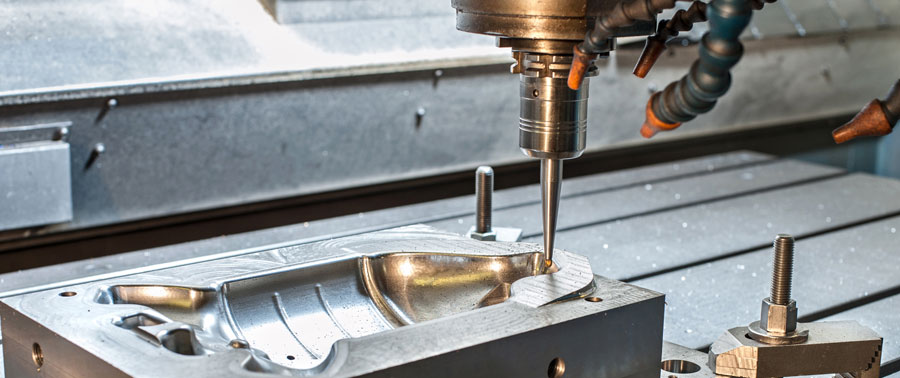

The die-casting process involves injecting molten aluminum into a mold cavity under high pressure. This method allows for the production of complex shapes with high dimensional accuracy and smooth finishes. The process is highly efficient, enabling the mass production of parts with consistent quality. The resulting parts can range from small components like connectors and housings to larger items such as engine blocks and structural elements.

2. Technical Difficulties of Die-Cast Aluminum Parts

While die-casting offers numerous advantages, it also presents several technical challenges that must be addressed to ensure the quality and functionality of the final parts.

A. Porosity

Porosity is a common defect in die-cast aluminum parts, characterized by tiny voids or air pockets within the material. These voids can weaken the structural integrity of the part and compromise its performance. Porosity typically arises from trapped air or gases during the casting process, inadequate mold design, or improper cooling rates.

B. Warping and Distortion

Due to the high thermal gradients involved in die-casting, parts can experience warping or distortion as they cool and solidify. This can lead to deviations from the intended dimensions and shapes, affecting the part's fit and function. Controlling the cooling rate and optimizing the mold design are crucial to minimizing these issues.

C. Surface Defects

Surface defects such as cracks, blisters, and rough finishes can occur due to various factors, including improper mold temperature, incorrect alloy composition, or insufficient die lubrication. These defects can impact the aesthetic appeal and mechanical properties of the parts.

D. Inconsistent Dimensions

Maintaining consistent dimensions across large production runs is a significant challenge in die-casting. Variations in mold temperature, injection pressure, and material properties can lead to dimensional discrepancies, necessitating rigorous inspection and quality control measures.

3. Main Detection Dimensions of Die-Cast Aluminum Parts

Accurate measurement and inspection are critical to ensuring the quality of die-cast aluminum parts. The primary dimensions and features that require inspection include:

A. Linear Dimensions

Linear dimensions, such as length, width, and height, are fundamental measurements that must conform to specified tolerances. These dimensions are critical for ensuring that parts fit together correctly in assemblies.

B. Geometric Tolerances

Geometric tolerances, including flatness, roundness, and perpendicularity, are essential for ensuring the proper function of the parts. These tolerances ensure that parts maintain their shape and alignment within acceptable limits.

C. Surface Finish

The surface finish of die-cast aluminum parts affects their appearance and performance. Inspecting surface roughness, texture, and any surface defects is crucial for meeting quality standards.

D. Feature Location

The accurate location of features such as holes, slots, and bosses is vital for the assembly and functionality of the parts. Any deviation from the specified locations can lead to assembly issues and performance failures.

4. The Important Position of Three-Coordinate in the Detection of Die-Cast Aluminum Parts

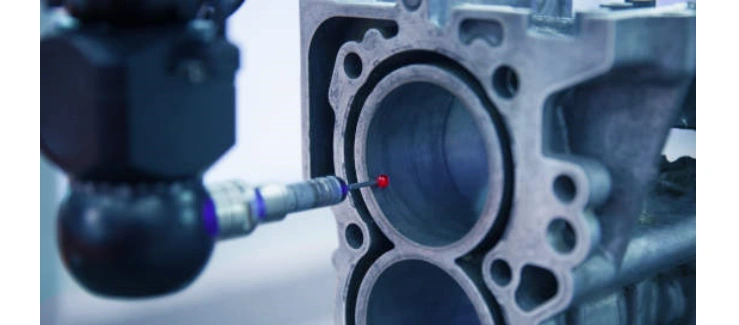

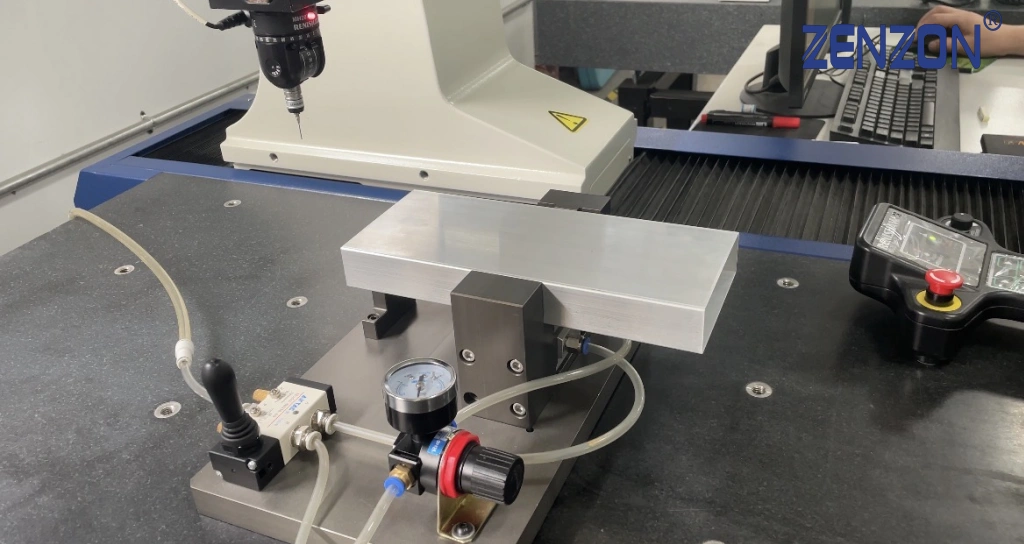

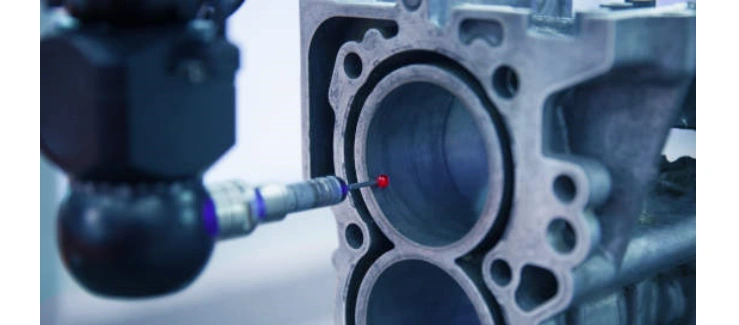

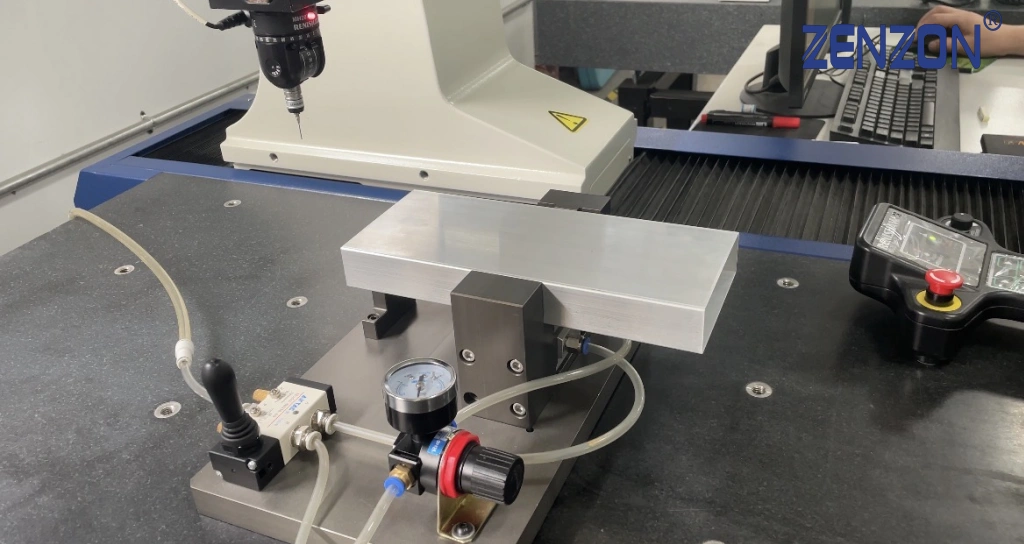

Coordinate measuring machines (CMMs) play an indispensable role in the inspection and quality control of die-cast aluminum parts. These advanced machines use a probing system to accurately measure the physical geometrical characteristics of an object, providing highly precise and repeatable measurements.

A. Precision and Accuracy

CMMs offer exceptional precision and accuracy, often within micrometers. This level of detail is essential for detecting even the smallest deviations from specified dimensions, ensuring that parts meet stringent quality standards.

B. Versatility

CMMs can measure a wide range of geometries and features, from simple linear dimensions to complex freeform surfaces. This versatility makes them ideal for inspecting the diverse shapes and sizes of die-cast aluminum parts.

C. Efficiency

Automated CMMs can perform inspections rapidly and with minimal human intervention, significantly reducing inspection times and increasing throughput. This efficiency is critical in high-volume production environments where timely inspections are necessary to maintain production schedules.

D. Data Collection and Analysis

CMMs are equipped with sophisticated software that enables detailed data collection and analysis. This data can be used to identify trends, perform root cause analysis, and implement continuous improvement initiatives, enhancing overall quality control processes.

E. Repeatability

The repeatability of CMM measurements ensures that inspections are consistent, reducing variability and enhancing confidence in the quality of the parts. This consistency is vital for maintaining high standards across large production runs.

Summary

In conclusion, die-cast aluminum parts are integral to many industries due to their excellent mechanical properties and manufacturing efficiency. However, producing high-quality die-cast aluminum parts involves overcoming significant technical challenges such as porosity, warping, surface defects, and dimensional inconsistencies. Accurate measurement and inspection of these parts are crucial to ensuring their quality, with primary focus areas including linear dimensions, geometric tolerances, surface finish, and feature location.

Coordinate measuring machines (CMMs) play a vital role in the inspection of die-cast aluminum parts, offering unmatched precision, versatility, efficiency, data collection capabilities, and repeatability. By leveraging the capabilities of CMMs, manufacturers can ensure that their die-cast aluminum parts meet the highest standards of quality, functionality, and performance. As a technician with extensive experience in this field, I can attest to the critical importance of meticulous dimensional inspection and the invaluable contribution of CMMs in achieving and maintaining excellence in die-cast aluminum parts production.