Dimensional inspection is a critical quality control process used in various manufacturing industries to ensure that components and products meet specified dimensions and tolerances. This article delves into the concept of dimensional inspection, its importance, and the crucial role of coordinate measuring machines (CMMs) in the dimensional inspection of mold production.

What is Dimensional Inspection?

Dimensional inspection involves the measurement and verification of physical dimensions of a manufactured part or product to ensure it adheres to the specified design and tolerances. This process can include checking lengths, widths, heights, diameters, angles, and other geometric properties. The purpose of dimensional inspection is to ensure that each part meets the stringent requirements set forth in the design specifications, ensuring functionality, compatibility, and quality.

Why is Dimensional Inspection Important?

Dimensional inspection is vital for several reasons:

1. Quality Assurance: It ensures that products meet the quality standards required for their intended use. Any deviation from the specified dimensions can lead to product failures, reduced performance, and customer dissatisfaction.

2. Compliance and Standards: Many industries have stringent regulatory requirements and standards that products must meet. Dimensional inspection helps manufacturers comply with these regulations, avoiding legal issues and potential recalls.

3. Cost Efficiency: Identifying dimensional inaccuracies early in the manufacturing process can prevent costly rework, scrap, and material waste. This leads to more efficient production processes and cost savings.

4. Interchangeability: In industries where parts from different manufacturers must work together (e.g., automotive, aerospace), dimensional accuracy ensures that components fit together seamlessly, maintaining the integrity and functionality of the final product.

5. Safety: In critical applications, such as medical devices or aerospace components, dimensional accuracy is directly linked to the safety and reliability of the product. Ensuring precise dimensions can prevent catastrophic failures.

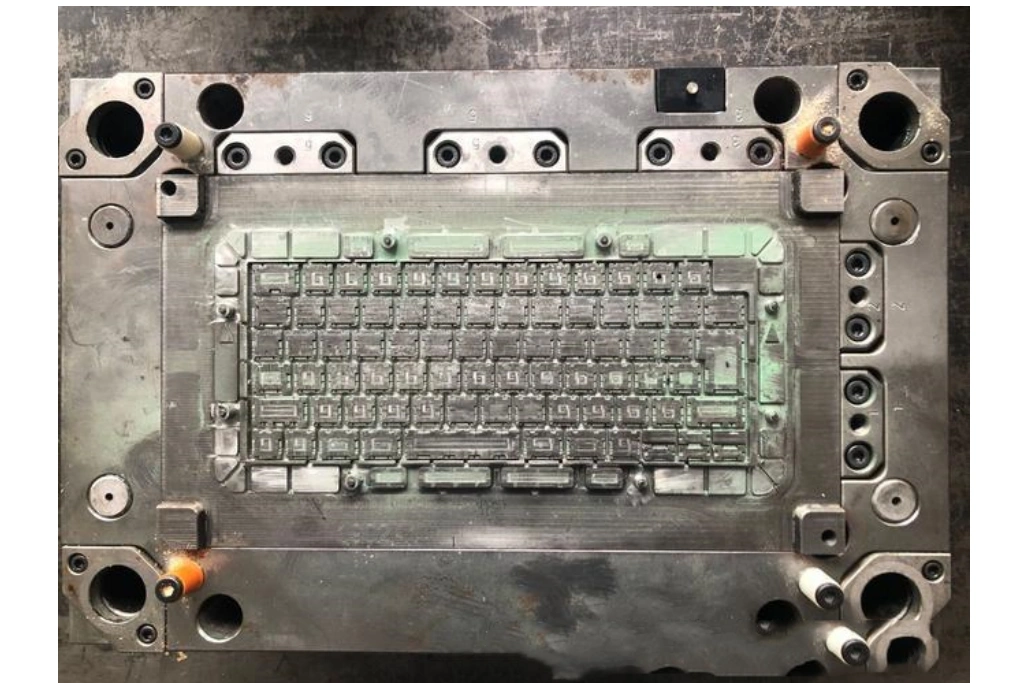

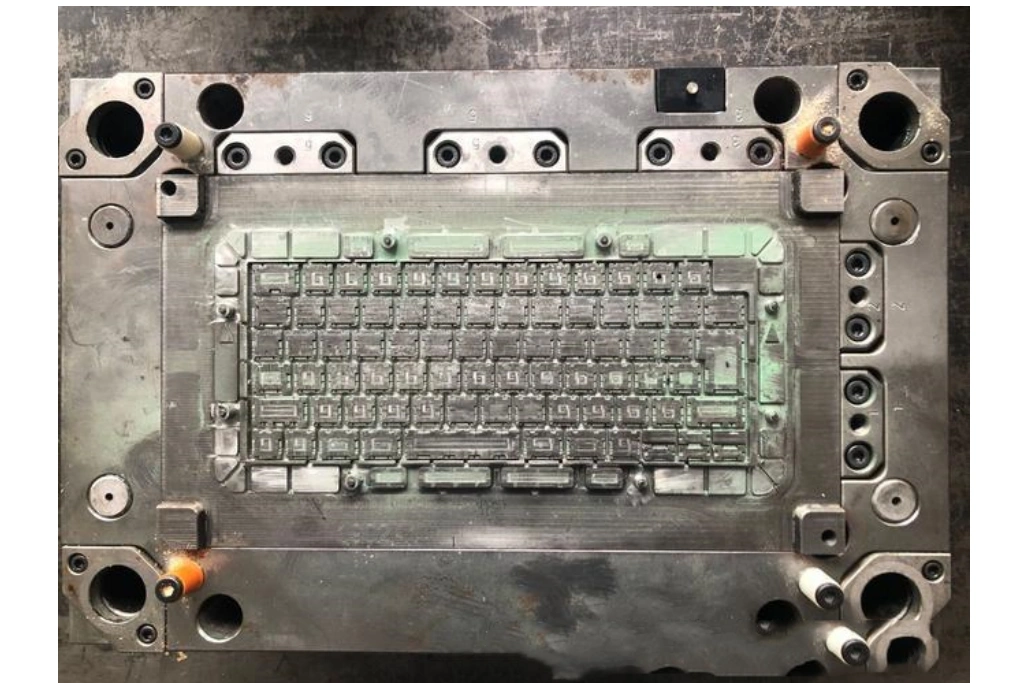

The Role of Coordinate Measuring Machines in Dimensional Inspection of Mold Production

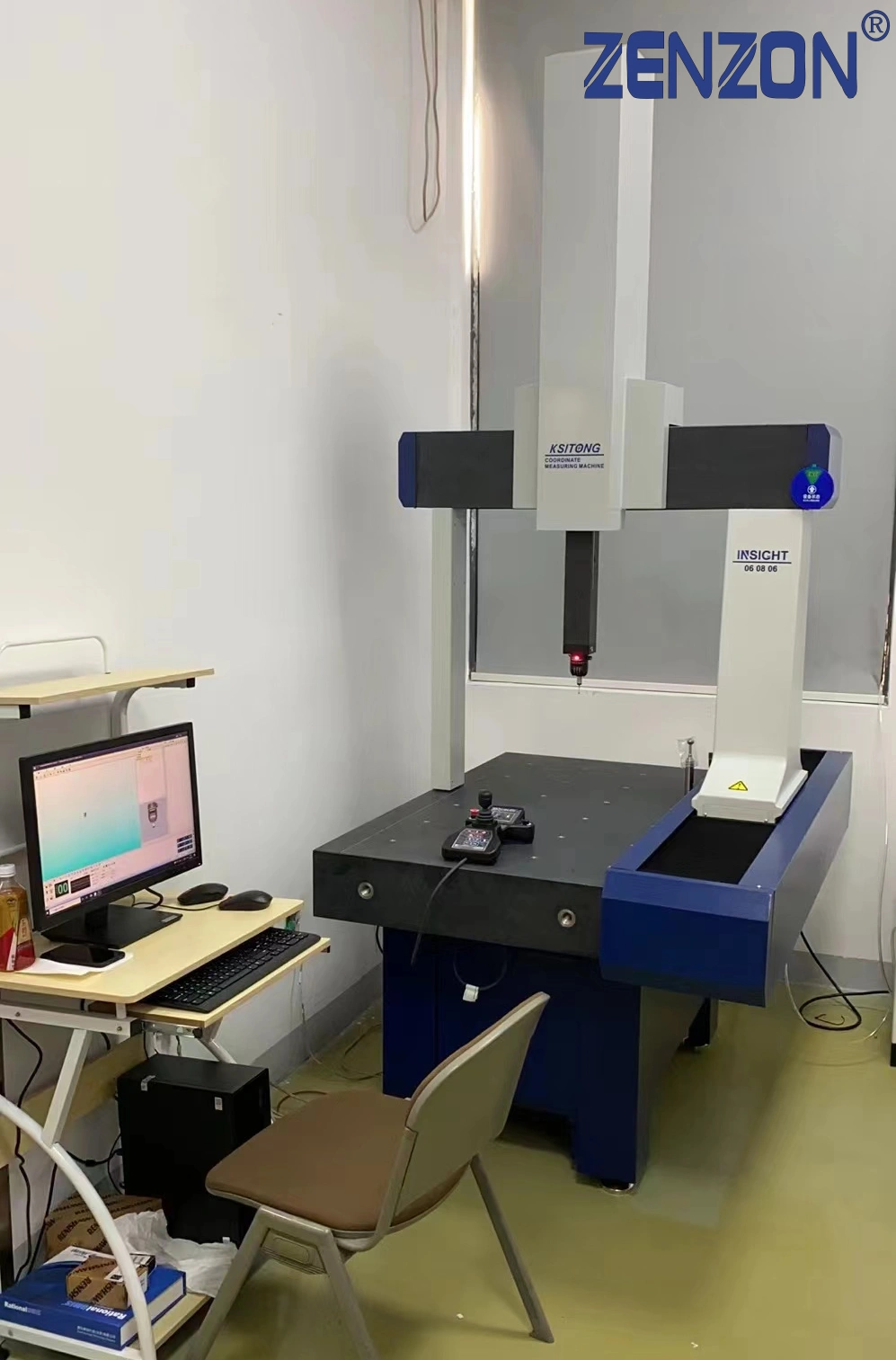

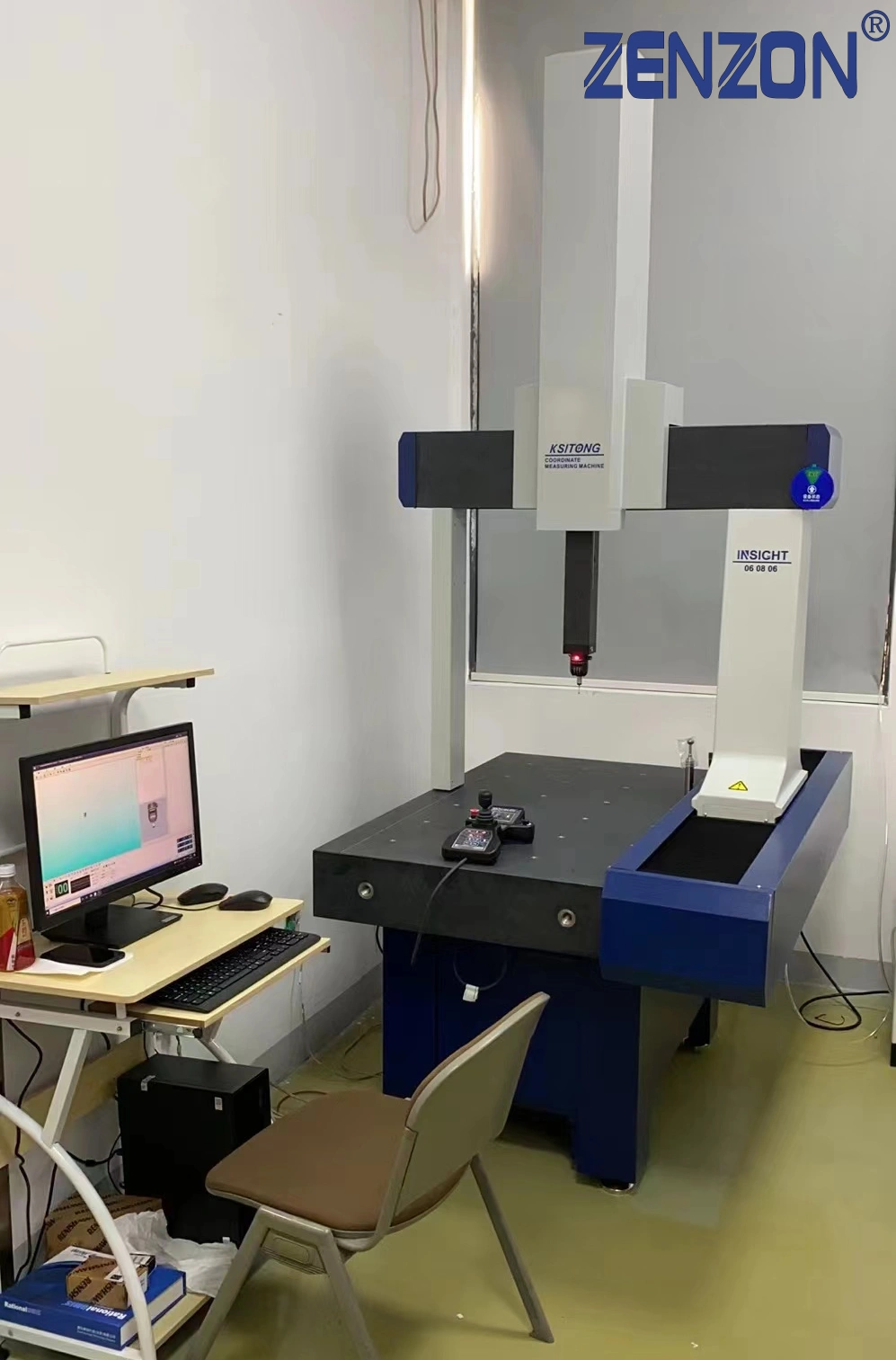

In mold production, the precision of the molds directly impacts the quality of the final products. This is where coordinate measuring machines (CMMs) come into play. CMMs are advanced devices used to measure the physical geometrical characteristics of an object. They play a pivotal role in the dimensional inspection of mold production for several reasons:

1. High Precision and Accuracy: CMMs provide highly accurate measurements, often down to micrometers. This level of precision is crucial in mold production, where even minor deviations can lead to significant issues in the final product.

2. Versatility: CMMs can measure complex shapes and geometries, making them ideal for inspecting molds that often have intricate designs. They can handle both simple and highly complex parts, ensuring comprehensive inspection coverage.

3. Efficiency: Automated CMMs can perform inspections much faster than manual methods, significantly reducing inspection times and increasing productivity. This efficiency is vital in mold production, where timely inspections can prevent delays in the manufacturing process.

4. Repeatability: CMMs offer consistent and repeatable measurements, reducing the variability associated with manual inspections. This repeatability ensures that every mold produced meets the same high standards.

5. Data Collection and Analysis: CMMs are equipped with software that allows for detailed data collection and analysis. This data can be used to identify trends, perform root cause analysis, and implement continuous improvement initiatives in the manufacturing process.

Summary

Dimensional inspection is a fundamental process in manufacturing, ensuring that products meet precise design specifications and quality standards. Its importance spans quality assurance, compliance, cost efficiency, interchangeability, and safety. In mold production, where precision is paramount, coordinate measuring machines (CMMs) play a crucial role. They offer high precision, versatility, efficiency, repeatability, and advanced data collection capabilities, making them indispensable tools in ensuring the dimensional accuracy of molds.

By integrating CMMs into the dimensional inspection process, manufacturers can enhance the quality of their molds, streamline production, and maintain the high standards required in today's competitive manufacturing landscape.