Product Characteristics:

Construction: Crafted from aluminum casting with a powder-coated finish for durability and aesthetics.

Motor Capability: Features a variable speed motor (available as an option) for enhanced versatility and precision.

Worktable: Equipped with a T-slot table made from a combination of stainless steel and aluminum alloy, offering strength and corrosion resistance.

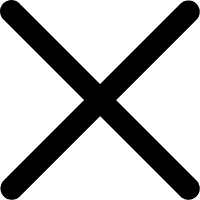

Clamping System: Incorporates fast cam locking vises crafted from 304 stainless steel, ensuring secure gripping and durability.

Illumination: Features LED chamber illumination for improved visibility and accurate cutting.

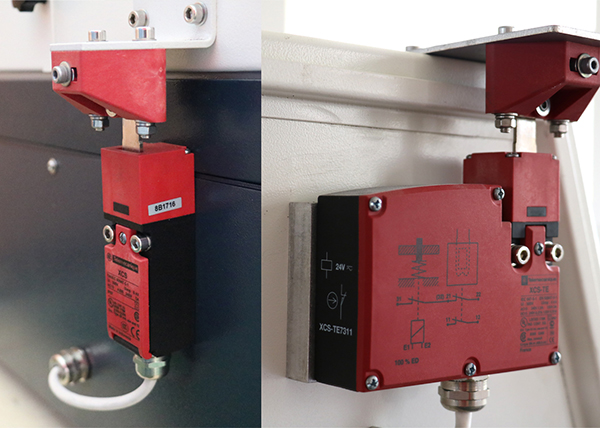

Braking System: Optionally equipped with an electronic braking system for swift and efficient blade stopping.

Side Port Window: Designed with a side port window to accommodate longer samples, enhancing the machine's flexibility.

Coolant System: Mobile plastic recirculation coolant tank for maintaining tool and workpiece integrity during cutting operations.

Workspace: Boasts a large workspace, ideal for accommodating various materials and cutting requirements.

Application:

The UniCUT 250, with its expansive workspace and diverse clamping vise options, is an ideal choice for material test laboratories as well as small-scale industrial or production environments.

Description:

The UniCUT 250 is a robust and durable tabletop manual abrasive cutter that utilizes a wheel feed mechanism. This versatile machine is engineered to cut through an extensive array of materials, ranging from ferrous and non-ferrous metals to fasteners, foundry castings, heat-treated parts, rocks, ceramics, and more. Its large workspace and diverse clamping vise options make it a perfect fit for material testing laboratories, while also catering to the needs of small industrial or production settings.